Laser Dust Collector

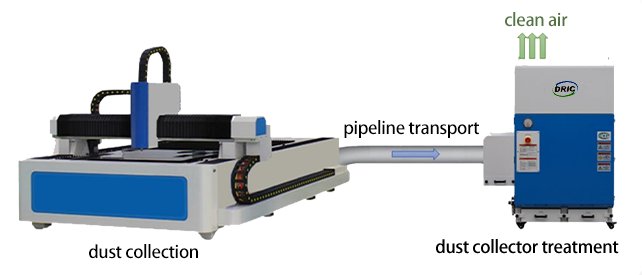

The Laser Cutting Dust Collector is an essential purification unit custom-engineered for modern cutting machines. It is designed to efficiently capture and filter the fine dust and smoke generated during the cutting process. DRIC classical plasma laser dust collector has these advantages:

Suitable for many metal laser cutting types: Carbon Steel Cutting, Stainless Steel Cutting, Aluminum Sheet Cutting and so on;

Suitable for many working enviroments: Automated Cutting Lines, Heavy Industry Plants, Laser Cutting Areas;

Equip with Anti-Static Cartridge+Spark Arrestor

Overview

Features

Key Features of Our Laser Dust Collector System:

Our Laser Cutting Dust Collection Equipment is built with cutting-edge technology:

Sustained Efficiency: Equipped with high-efficiency filter cartridges and an automatic pulse cleaning system, guaranteeing continuously stable suction and significantly extending filter lifespan.

Enhanced Safety: Features a built-in spark arrestor and robust flame-retardant measures to effectively manage cutting sparks, particularly crucial for the Explosion Proof Laser Cutter variant, ensuring high operational security.

Intelligent Operation: The integrated smart control system allows for linkage with the cutting machine (start/stop), making operation highly convenient and energy-efficient

*Choosing right plasma laser fume extraction, please read How to choose the right laser fume extractor

Application of Laser Dust Collector

*If you need case about this laser cutter fume extractor, please click here.

Cutting Types: Suitable for various cutting equipment, including laser and plasma, handling materials such as carbon steel, stainless steel, and more.

Working Conditions: Perfect for high-speed cutting, thick plate cutting, and precision cutting operations requiring effective Laser Cutting Fume Purification and dust removal.

Technical Data

Model | LW-S-1204-055 | LW-S-1206-075 | LW-S-1209-110 |

|  |  | |

Approximate Size (W*L*H) | 1100*1110*1970 mm | 1110*1110*2620 mm | 1520*1220*2730 mm |

Motor Power | 5.5Kw | 7.5Kw | 11Kw |

Process Capacity | 4000-5000 m³/h | 5500-6500m³/h | 8000-9000m³/h |