-

Fluoride

FluorideRemoval Rate: 90%

-

SS

SSRemoval Rate: 83%

-

TP

TPRemoval Rate: 80%

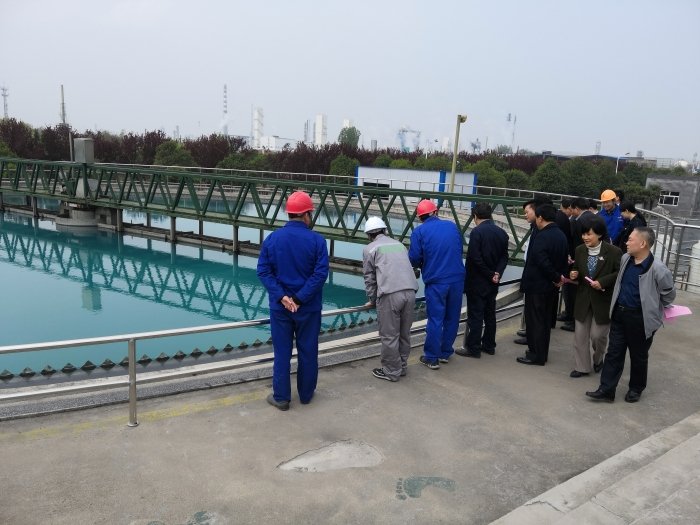

Introduction

Coal chemical plants face growing challenges in meeting stringent fluoride discharge standards for industrial wastewater. A breakthrough 24,000 m³/day wastewater treatment upgrade in Shandong's Tengzhou City demonstrates how complexation-based deep defluoridation technology can achieve stable compliance at remarkably low costs. This coal chemical wastewater treatment case study showcases an innovative retrofit of existing infrastructure that solved persistent fluoride while keeping chemical costs below $0.13/m³.

Project Overview

Wastewater Characteristics & Challenges

The plant's biologically treated effluent and circulating blowdown water contained:

Fluoride (5.0-9.0 mg/L) - exceeding local standards

Suspended solids (30-60 mg/L)

Total phosphorus (1.2-1.5 mg/L)

Existing system failed to consistently meet DB37/3416.1-2018 for Nansi Lake Basin (<1.0 mg/L fluoride)

Innovative Treatment Solution

The upgrade utilized:

Retrofitted Existing Infrastructure

Modified original three-stage flocculation sedimentation system

Minimal capital investment required

Complexation Deep Defluoridation Technology

Selective fluoride removal mechanism

Low chemical consumption (0.6-0.9 RMB/m³)

Stable performance across water quality fluctuations

Key System Advantages

80-90% fluoride removal efficiency

Simultaneous SS and TP reduction

Minimal sludge production

Easy integration with existing processes

Performance & Results

Treatment Efficiency Metrics

| Parameter | Influent | Effluent | Removal Rate |

| Fluoride | 9.0 mg/L | ≤ 1.0 mg/L | 90% |

| SS | 60 mg/L | ≤ 10 mg/L | 83% |

| TP | 1.5 mg/L | ≤ 0.3 mg/L | 80% |

Economic & Regulatory Benefits

Chemical costs: Just 0.6-0.9 RMB/m³ ($0.09-0.13/m³)

Full compliance with Nansi Lake Basin standards

No major infrastructure expansion required

Operational simplicity for plant staff

Conclusion

This coal chemical wastewater treatment upgrade proves that advanced defluoridation technologies can solve compliance challenges without expensive plant overhauls. The project's success - achieving consistent fluoride levels ≤1.0 mg/L at minimal operating cost - makes it a model for industrial wastewater treatment upgrades across China's coal chemical sector. For plants facing similar fluoride discharge challenges, this case demonstrates how smart process retrofits can deliver both regulatory compliance and economic efficiency.

*Contact us today, get free coal chemical wastewater solution!

Request Quote

Tell us your inquiry, we will recommend a suitable product model or solution for you!