For every welder, manual or robotic, the battle against toxic fumes is a constant challenge. Traditional solutions like ventilation systems often fall short, leaving you exposed. This is where on torch welding extraction technology shines. By capturing fumes directly at the source, right as they are created, these systems offer unparalleled protection. Understanding the nuances of MIG welding on torch extraction is key to unlocking a cleaner, safer, and more productive workshop. This guide will explore the critical factors that determine the success of high-vacuum extraction systems, ensuring you get the performance you need.

Why On-Torch Extraction is the Superior Choice for Fume Control

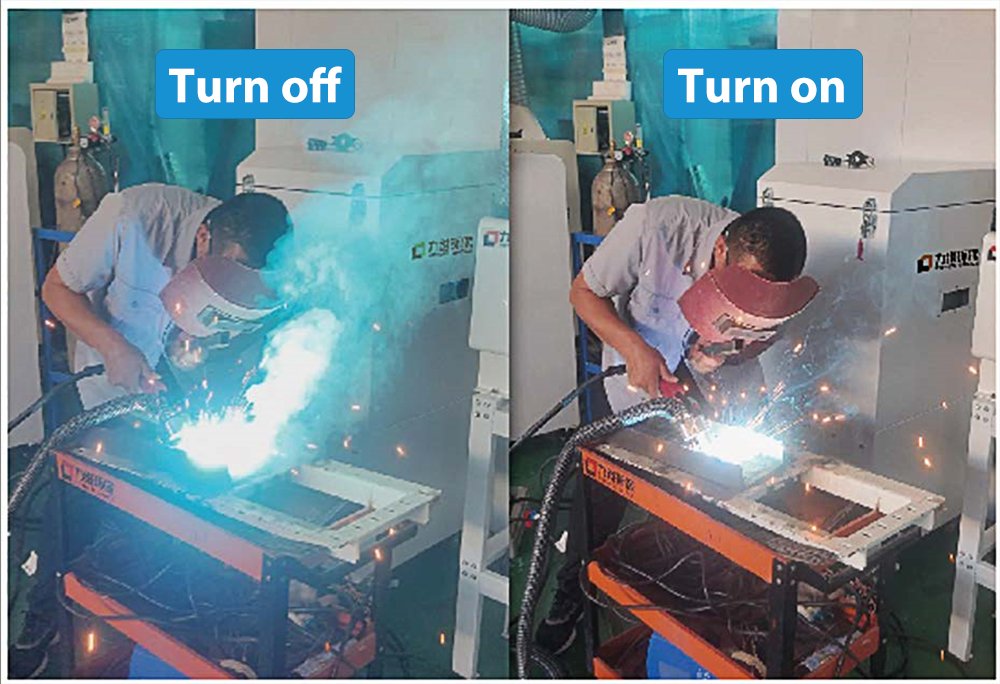

Before diving into the details, it's clear why at-source extraction is the gold standard. Unlike downdraft tables or overhead hoods that allow fumes to spread, on torch welding extraction captures over 90% of contaminants before they ever reach your breathing zone. This means a healthier work environment, compliance with strict safety regulations, and improved visibility of the weld pool for better quality welds. For both manual operators and automated cells, MIG welding on torch extraction is the most efficient and effective method to control hazardous airborne particles.

Key Factors Affecting On-Torch Welding Extraction Performance

A high-vacuum extractor is a powerful tool, but its effectiveness isn't guaranteed. Several factors directly on the

welding line significantly influence its smoke-capturing efficiency. Ignoring these can lead to poor performance, regardless of the unit's power. Let's break down the most critical elements you need to manage.

Welding Position

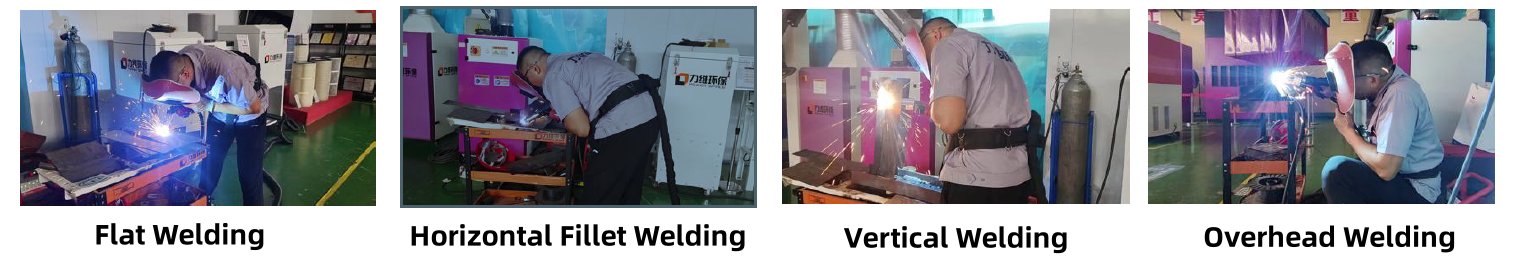

The position of your weld greatly impacts how fumes behave and how well they can be extracted.

Flat and Horizontal : These are the easiest positions for on torch welding extraction. Fumes rise naturally into the extraction nozzle, making capture highly efficient.

Vertical: Here, fumes travel upward along the workpiece. The extractor must work against gravity to pull the smoke sideways into the nozzle. Optimal nozzle placement and strong vacuum are crucial.

Overhead: This is the most challenging position. Fumes rise away from the nozzle, which is often pointing upwards. This requires a very strong vacuum and precise nozzle positioning to effectively capture the smoke before it disperses into the air.

This unit is better suited for horizontal and flat welding. Compatible with a 350A welding gun featuring a tapered air inlet, it achieves a fume and dust capture rate of 80% when welding 8mm thick steel plates.

Extraction Nozzle Design

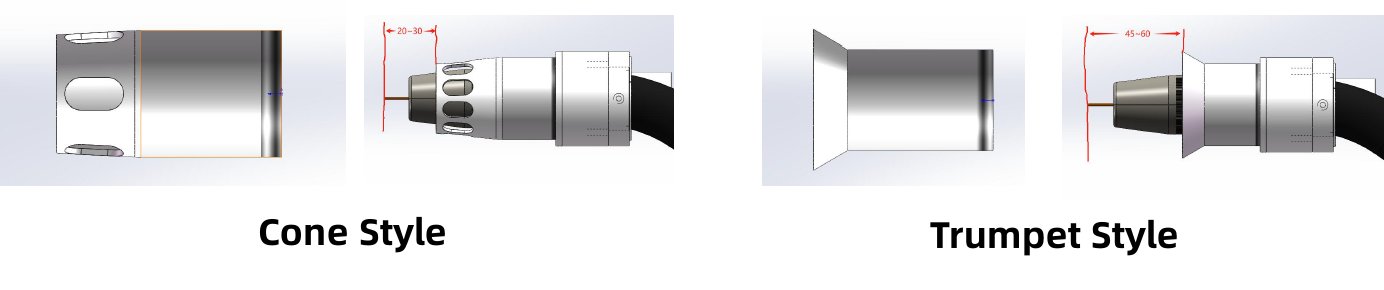

The nozzle is the point of contact with the fume plume, and its design is not one-size-fits-all.

Trumpet Nozzles: These are excellent for capturing a large volume of smoke from a broader area. They are often preferred for general MIG welding on torch extraction where the weld pool is larger.

Conical Nozzles: These nozzles create a more focused, high-velocity airflow. They are ideal for reaching into tight spaces, for precise welds, or for applications where a standard bell nozzle might cause interference with the joint or fixture.

Distance Between Nozzle and Arc

This is perhaps the most critical factor. The extraction nozzle must be kept as close to the arc as possible—typically within 20-60 mm. The strength of the vacuum decreases dramatically with distance. If the nozzle is too far, the suction power will be too weak to capture the fine particulates, and the fumes will escape.As shown above, DRIC recommends an optimal distance of 20mm between the torch nozzle and the Cone Style attachment, and 45mm for the Trumpet Style.

These are reference values and can be fine-tuned based on actual welding conditions. Need assistance? Consult our experts

Workpiece Interference and Torch Size

The theory is simple, but practice requires planning. For on torch welding extraction to work, the extraction nozzle must have a clear path to the weld joint.

Workpiece Interference: Complex fabrications, tight corners, or internal joints can physically block the nozzle. While robotic welding systems are often programmed to maintain a perfect angle and distance, manual welders must be mindful of their technique to avoid the nozzle catching on the workpiece.

Torch Size and Kit Compatibility: Not all extraction kits fit all torches. The physical size and style of your MIG gun determine which extraction kit can be installed. Choosing the wrong kit will lead to poor performance and potential damage to your equipment.

Discover the Solution: Power Space LW17 Series On Torch Extraction

Navigating these factors to find the perfect setup can be complex. This is where the LW17 series on torch welding extraction system from Power Space comes in. Engineered for high performance and reliability, the LW17 series is designed to deliver the powerful, consistent vacuum needed to tackle all welding positions and challenges. Power Space offers a wide range of compatible extraction kits tailored to fit most major torch brands and models, eliminating the guesswork and ensuring a perfect, interference-free match for your specific application.

Ready to find your perfect fit? Click the link to contact our extraction experts today. We will help you confirm if the LW17 series is right for your needs and recommend the ideal extraction kit and product model for your torch and workflow.

Request Quote

Tell us your inquiry, we will recommend a suitable product model or solution for you!