Laser cutting operations generate hazardous fumes and particulate matter that require professional extraction solutions. A properly designed laser cut dust collector is essential for maintaining clean air quality, protecting equipment, and ensuring regulatory compliance. Understanding how laser dust collection systems work helps users select the right solution for their specific laser cutting applications and avoid common mistakes that compromise performance and safety.

How Laser Cutting Dust Collection Works

The Three-Component System

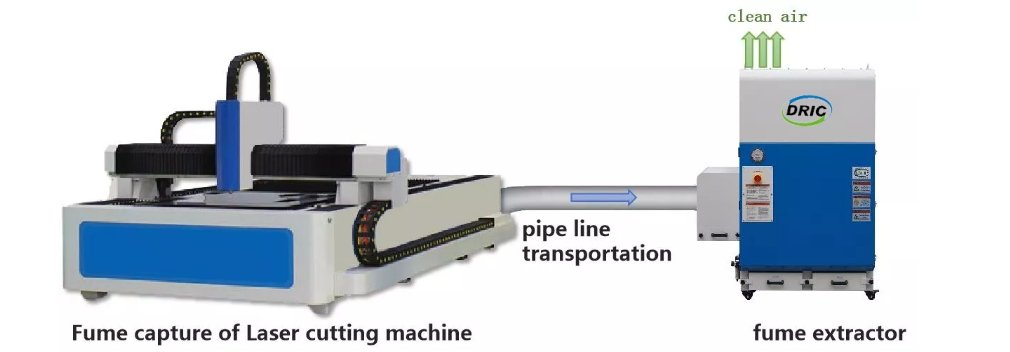

Effective laser cut dust collector consists of three integrated components:

Smoke Capture at Source

Machine bed dust collection system

Flow path design optimization

Capture point positioning and sizing

Specialized hoods and enclosures

Pipeline Transportation

Machine bed smoke transport piping

Connection piping from bed to collector

Proper duct sizing and layout

Minimizing pressure loss

Dust Collector Unit

Provides suction power source

Filters and purifies captured smoke

Automated filter cleaning systems

Safe discharge of clean air

(Laser Dust Collection Working Principle)

Advanced Bed Zone Collection Technology

Partitioned Dust Collection Structure

Modern laser cutting systems use innovative zone-based collection:

1-meter intervals: Bed divided into sections approximately 1 meter apart

Independent air inlets: Each zone has dedicated capture points

Automatic valves: Zone-specific valves activate based on cutting head position

Following movement: Only zones where cutting occurs remain active

(Laser Cutting Machine Bed Zone)

Collection Efficiency Factors

High-Efficiency Systems Feature:

✅ Tracking valves that follow cutting head movement

✅ Properly sized capture openings

✅ Optimized airflow design

✅ Integrated scrap management carts

Low-Efficiency Systems Often Have:

❌ Fixed open inlet design (no tracking valves)

❌ Undersized capture openings

❌ Poor airflow management

❌ Inadequate scrap handling

(Wrong laser dust removal way)

Key Benefits of Professional Dust Collection

Health & Safety Protection

Reduces operator exposure to hazardous fumes

Prevents respiratory problems and health issues

Meets OSHA and workplace safety regulations

Equipment Protection

Prevents optical lens contamination

Reduces electronic component damage

Extends machine lifespan

Production Quality

Improves cutting quality by removing smoke interference

Reduces cleaning time between operations

Maintains consistent production environment

Common Mistakes to Avoid

Inadequate System Sizing

Choosing undersized collectors for machine capacity

Ignoring material-specific fume generation rates

Underestimating required airflow volume

Poor Installation Practices

Incorrect duct sizing and routing

Too many bends and restrictions

Leaky connections reducing efficiency

(Don't use soft PVC pipe)

Neglecting Maintenance

Delaying filter replacement

Ignoring pressure differential readings

Not emptying collection bins regularly

The Professional Solution: LW12 Series Laser Cut Dust Collector

Why Choose This System?

Universal Compatibility:

Works with fiber laser models

Adaptable to various machine sizes (3015, 4020, 6020, etc.)

Suitable for diverse materials (metal, plastic, composites)

Advanced Features:

✅Smart zone control technology

✅Auto-cleaning filters reduce maintenance

✅Energy-efficient operation

✅Real-time monitoring systems

Power Space Expert Services

Comprehensive support includes:

Free Technical Consultation

Provide your laser machine specifications

Share your typical materials and workload

Get expert recommendations

Customized System Design

Perfectly matched laser cut dust collector

Complete ductwork and accessory package

Installation guidance and support

Ongoing Maintenance Support

Filter replacement programs

Performance optimization

Technical support hotline

Conclusion

Choosing the right laser cut dust collector requires understanding both your equipment needs and the technology behind effective fume extraction. The zone-based collection system used in modern laser cutting, when combined with a properly sized laser cut dust collector, ensures optimal performance and compliance. The LW12 series from Power Space offers a comprehensive solution backed by expert support and tailored to your specific requirements.Next Step: Contact Power Space with your laser machine details for a customized dust collection solution that actually works.

Request Quote

Tell us your inquiry, we will recommend a suitable product model or solution for you!